Curio

Curio started as a simple idea to combine my passion for engineering with the growing world of 3D printing. I was hands-on in every phase, transforming concepts into customer-ready products.

Ideation

Identifying a Niche

The idea for Curio came from observing a gap in the market for small, high-quality 3D-printed components. I saw a unique niche for Curio to cater to STEM enthusiasts and 3D-printing hobbyists who wanted quality components but didn’t have access to 3D-printing resources themselves.

Understanding Consumers

Curio aimed to make 3D-printed products accessible and affordable. I spoke with teachers, engineers, remote workers, and basically anyone who was interested to understand the possible users.

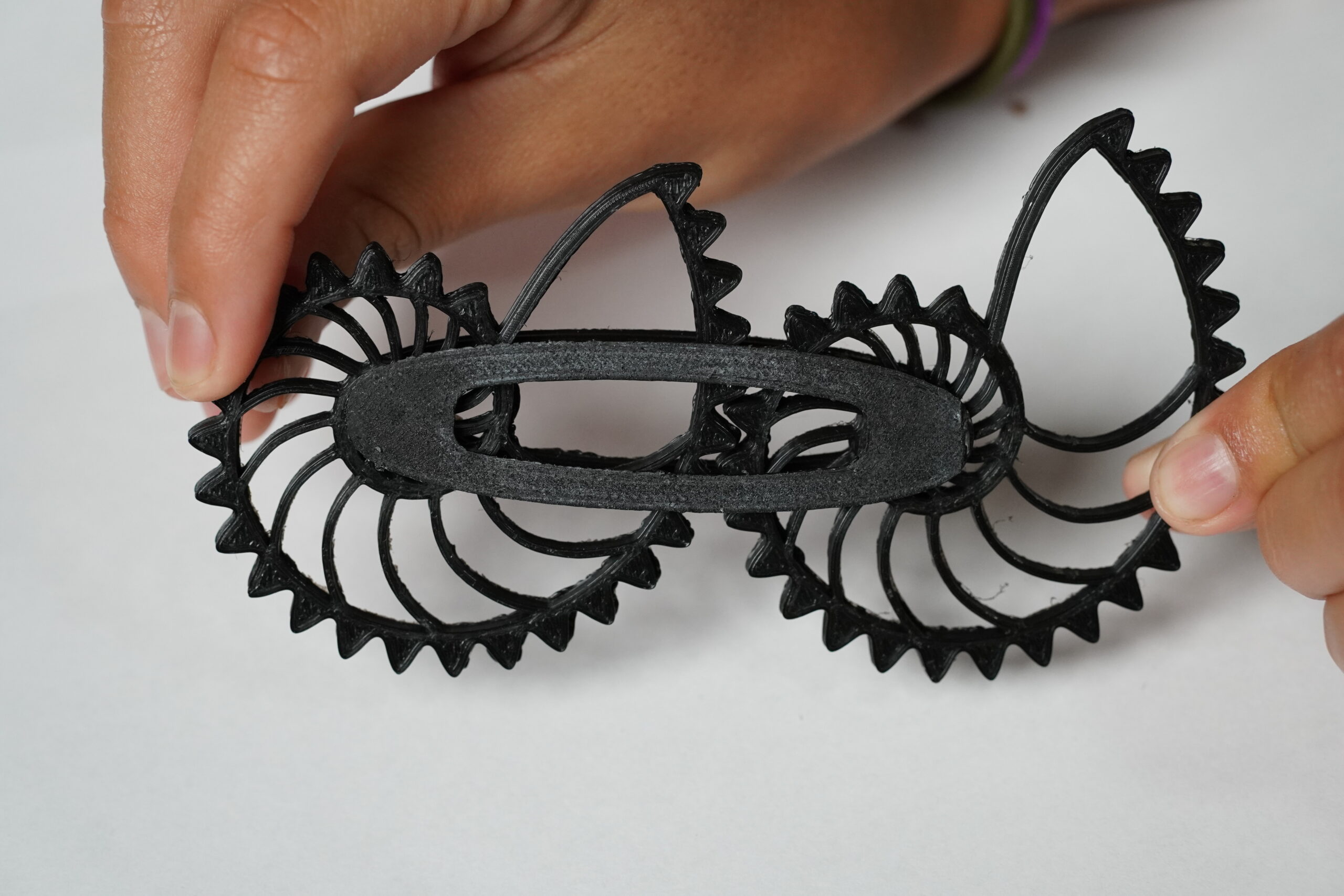

Prototyping

Using CAD tools, I developed and iteratively tested prototypes, creating multiple MVPs based on my conversations with users. Each design refinement focused on enhancing functionality and optimizing the user experience, ensuring each product met customer needs.

Growing a Community

With products ready for market, I built a website, launched an Etsy store, and grew my customer base through campus marketing and word-of-mouth. Networking was key—I connected with students, engineers, and business enthusiasts who supported Curio and helped spread the word.

Continuous Improvement

As Curio gained traction, with monthly sales around 10-30 units, I maintained close contact with customers to gather feedback and improve product quality. I experimented with new marketing strategies, production methods, and product offerings, continually evolving Curio to better serve the growing customer base.